After a bit of thought, some googling and digging through some dusty photos, I reckon that I bought my first pair of tubeless wheels and tyres way back in 2004. In the (slightly scary) 14 years that have zoomed by since my first introduction to the joy (and occasional heartache) of running tubeless tyres on my bikes, I've used a ridiculous number of different set-ups. And by used, I mean bought (or begged/borrowed/stole), tested, trained on and raced on.

I've tried factory tubeless systems, after-market set-ups, homemade ghetto versions, and everything from reasonably cheap to the hilariously expensive. So, I thought I was pretty au-fait with their foibles, but also, I knew that despite some of the downsides of running tubeless, I was hooked.

When the chance came up to test some Vee brand tubeless-ready CX tyres I jumped at it. Vee probably isn't a tyre brand that many cyclists would have heard of, but they've been around since 1977 and their website claims they are "the leading manufacturer of tires in Thailand for the automative sic, motorcycle and biking industries". They offer four tyres in their Cyclocross/Gravel range, two low-profile tyres (suitable for super-fast, dry conditions) and two slightly more UK-centric ones, the T-CX and its slightly racier brother, the CXV.

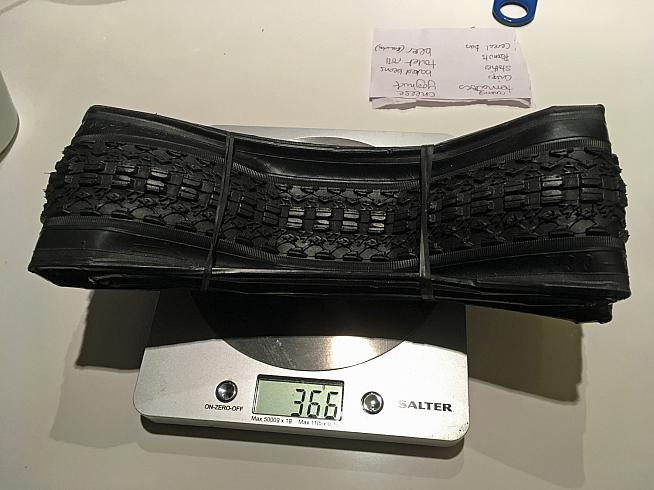

When my test pair of T-CX tyres arrived, first impressions were great. Decently light in this 33C width (366g on my digital scales, versus a claimed 400g), a tread pattern that looked like a mash-up of all my favourite racing treads from the past, and subtle graphics - so far so good.

As anyone who has ever tried fitting tubeless CX tyres (or any tubeless tyres for that matter), there's a definite knack to it and most time-served mechanics will have a system in place to get the tyres fitted and working with as little hassle as possible.

My workflow is as follows:

- Unpack the tyres and fit them on a spare wheel with an inner tube. Inflate to max tyre pressure and leave them for a few days. This takes any kinks/creases out of the casing and makes it as spherical as possible which can help with sealing.

- On the day of fitting, remove the old tubeless tyres from the wheels on which the new tyres are going to be fitted, clean the rim so that there's no old sealant left on it. Give the valve a good clean too and remove the valve core.

- Check the condition of the tubeless rim strip (if fitted) and repair/replace if necessary.

- Remove the now stretched new tyre from the spare wheel and mount correctly on the freshly cleaned rim on which they're going to be used. Obviously, at this point, it's a legal requirement to get the tyre logos correctly lined up with the valve hole.

- Make sure the new tyre is seated properly - I normally 'pat' the top of the tyre all around the circumference to make sure it's seated in the centre of the rim.

- Using a syringe, inject the appropriate amount of your favourite tubeless sealant through the valve into the tyre cavity - this is one of the benefits of removing the valve core. I've tested quite a few different sealants over the years, but stick with Stan's - it's expensive, but is durable and reliable.

- Do the 'Shake'n'Vac' - for any children of the 80s this should make perfect sense. For anyone else, it just means hold the wheel horizontally and shake it gently, working your way around the circumference, then turn over and repeat. This should coat the inside of the tyre/rim with sealant.

Now you should be ready to inflate. I generally try a good quality track pump first - a decent tyre with a good fit should inflate easily. If there's no joy with this, then I switch to my secret weapon, an ancient (empty) fire extinguisher, which I pressurise to around 140psi using the in-built Schrader valve and then connect to the tyre valve via a piece of tubing and an old track pump head.

If that doesn't work then I'll try liberally soaping the junction between the tyre and the rim with a high concentration of soapy bubbles (not too wet - think cappuccino foam for the perfect texture).

If even that doesn't work, then my last resort is to use a CO2 cartridge. I try not to use them as they're an environmental disaster, but sometimes it's the only thing that will work!

Hopefully one of those methods will get the tyre to 'pop' nicely - the bead of the tyre magically meets the rim with a satisfying pop and the thing should be sealed. I then top it up to the max allowed tyre pressure with a track pump and repeat the Shake'n'Vac process.

It's normally right about now that my wife comes outside to ask why I'm still faffing about with the bike and can we actually go riding yet?

I'd love to say that my magic method for fitting tubeless tyres worked like a dream on the Vee T-CX tyres, but I'd be lying. Nothing worked. I tried every trick I knew and all that happened was that I mentally and physically ran out of energy and the sealant leaked out and formed a dismal little puddle on the floor.

Eventually I gave up and took the wheels to my local bike shop, where the friendly mechanic let me use their air compressor to try and do the job. Initially, even with a compressor, no joy. The tyres stubbornly refused to 'pop' and all that happened is that the air leaked around the gap between the rim and the tyre.

Eventually, with lots of under-our-breath swearing, plenty of patting the tyre to make sure the bead was seated properly, and a dollop of luck, they did seal. But it must have taken 15 minutes. And this is on top of the hours I'd already spent faffing about with them.

I think it would be fair to say I wasn't that impressed so far.

I headed home, topped the tyres up with more sealant using a syringe (hoping that the tyre stayed sealed to the rim despite the fact I had to remove the valve core to get the sealant in - luckily it did), re-did the 'Shake'n'Vac' thing and then left them lying horizontally on the bench in my workshop - apparently a recommended way of helping errant tubeless set-ups to seal. I came back in the morning expecting to be able to fit the wheels and hit the trail.

But no. As I walked into the workshop I noticed the sidewalls of the tyres were white and it was obvious that tyre sealant was oozing through the casing. To be fair, there was probably still some soap bubbles mixed with the sealant as I'd tried that before heading to the bike shop, but I'd topped the sealant up again before leaving it overnight, so the percentage of soap bubbles should have been pretty low and with previous tyres that I used this method on, the sealant stays inside the tyre.

So, not only were the tyres a total nightmare to fit/seal in the beginning, even once fitted they were porous and let the sealant permeate through the casing. The tyre pressures had dropped from around 80psi from the night before to less than 20psi in the morning.

To say I wasn't impressed would be an understatement. These were by the far the hardest tubeless tyres I'd ever tried to fit, and even once fitted, they weren't airtight and they'd spent the whole night losing sealant through the sidewalls.

I'd love to say that in the end, the superb ride quality, outstanding grip and low drag coefficient made the fitting hassles worth the effort, but I can't say that - because I didn't trust them to hold air well enough to even get me to the end of the street, let alone further than that.

I didn't even try and ride them; I took them off, and they're now sitting forlornly in the corner of the workshop with a metaphorical return to sender label on them.

Yes, you could use them with inner tubes I guess, but what the hell is the point in that! Ultimately, they're £40 each and they don't work in the way that they're supposed to.*

It's possible that I got a duff pair to test, but based on these ones, my advice would have to be to avoid them at all costs and buy a pair of 'real' tubeless CX tyres from one of the more recognised brands instead.

Sorry Vee, but I'm out.

Vee T-CX tyre, £39.99 from www.veetireco.co.uk.

*The US website of Vee Tire Co claims the 120 TPI version of the T-CX tyre (as tested) is tubeless ready, whereas their UK website makes no reference to the tyre's tubeless capability. We have contacted Vee Tire Co for clarification.

0 Comments